Researchers from the University of Minnesota, with support from Medtronic, have developed a process for multi-material 3D printing of models of the heart’s aortic valve and the surrounding structures that mimic a real patient.

These patient-specific organ models, which include 3D-printed soft sensor arrays integrated into the structure, are fabricated using specialised inks and a customized 3D printing process. Such models can be used in preparation for minimally invasive procedures to improve outcomes in patients.

The research is published in Science Advances, a peer-reviewed scientific journal published by the American Association for the Advancement of Science (AAAS).

The researchers 3D printed the aortic root, consisting of the aortic valve and the openings for the coronary arteries. The aortic valve has three leaflets, surrounded by a fibrous ring. The model also included part of the left ventricle muscle and the ascending aorta.

“Our goal with these 3D-printed models is to reduce medical risks and complications by providing patient-specific tools to help doctors understand the exact anatomical structure and mechanical properties of the specific patient’s heart,” said Michael McAlpine, a University of Minnesota mechanical engineering professor and senior researcher on the study. “Physicians can test and try the valve implants before the actual procedure. The models can also help patients better understand their own anatomy and the procedure itself.”

This organ model was specifically designed to help doctors prepare for a transcatheter aortic valve replacement (TAVR) in which a new valve is placed inside the patient’s native aortic valve.

The aortic root models are made by using CT scans of the patient to match the exact shape. They are then 3D printed using specialised silicone-based inks that mechanically match the feel of real heart tissue the researchers obtained from the University of Minnesota’s Visible Heart Laboratories.

Physicians can use the models to determine the size and placement of the valve device during the procedure. Integrated sensors that are 3D printed within the model give physicians the electronic pressure feedback that can be used to guide and optimize the selection and positioning of the valve within the patient’s anatomy.

“As our 3D-printing techniques continue to improve and we discover new ways to integrate electronics to mimic organ function, the models themselves may be used as artificial replacement organs,” said McAlpine, who holds the Kuhrmeyer Family chair professorship in the University of Minnesota Department of Mechanical Engineering. “Someday maybe these ‘bionic’ organs can be as good as or better than their biological counterparts.”

The research was funded by Medtronic, the National Institute of Biomedical Imaging and Bioengineering of the National Institutes of Health, and the Minnesota Discovery, Research, and InnoVation Economy (MnDRIVE) Initiative through the State of Minnesota. Additional support was provided by University of Minnesota Interdisciplinary Doctoral Fellowship and Doctoral Dissertation Fellowship awarded to Ghazaleh Haghiashtiani.

Source CardiovascularNews

Duc Tin Clinic

Tin tức liên quan

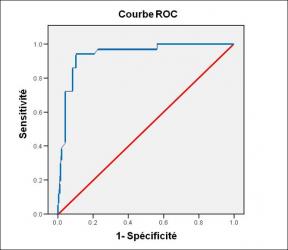

Performance diagnostique de l’interféron gamma dans l’identification de l’origine tuberculeuse des pleurésies exsudatives

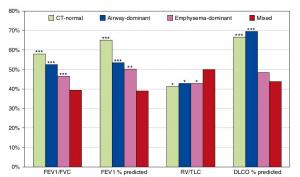

A Mixed Phenotype of Airway Wall Thickening and Emphysema Is Associated with Dyspnea and Hospitalization for Chronic Obstructive Pulmonary Disease.

Radiological Approach to Asthma and COPD-The Role of Computed Tomography.

Significant annual cost savings found with UrgoStart in UK and Germany

Thrombolex announces 510(k) clearance of Bashir catheter systems for thromboembolic disorders

Phone: (028) 3981 2678

Mobile: 0903 839 878 - 0909 384 389